1 / 0

Manufacturer

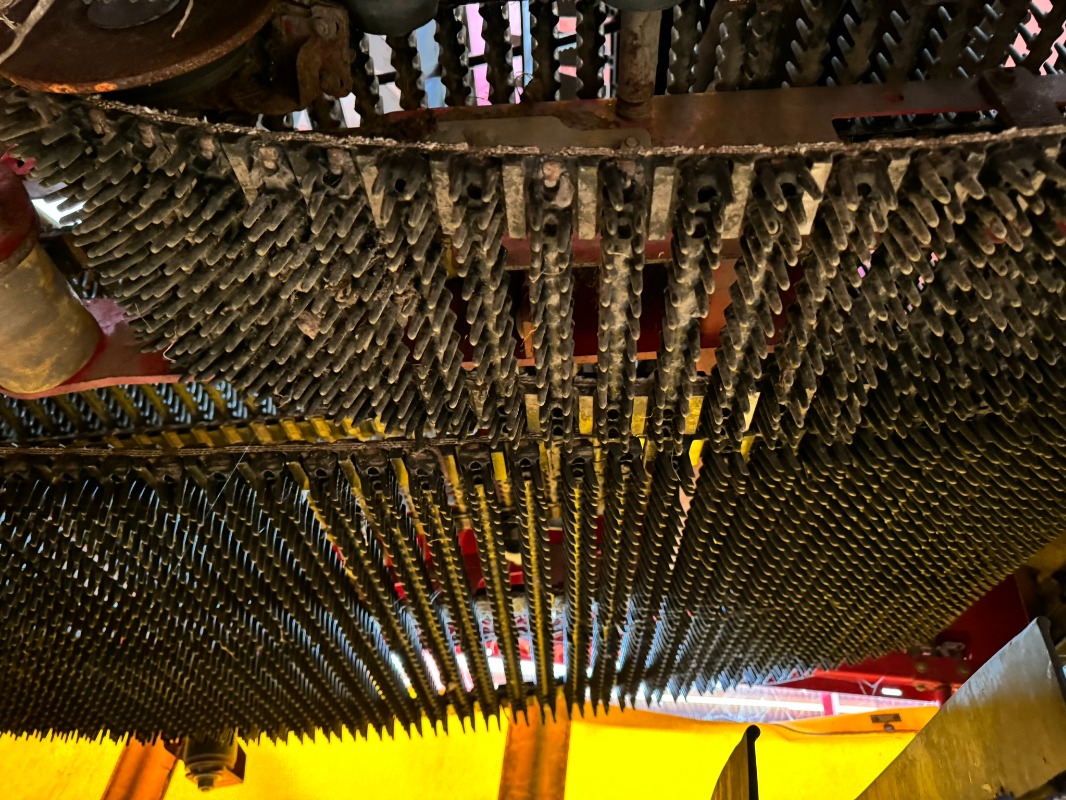

GRIMME

Category

Harvesting Technology

Serial number

12502073

Year of construction

2019

Operating data

200 ha

Condition

used

Refurbishment status

Unprocessed, without warranty claim

Configuration

Contact person

Do you have further questions or would you like to see the machine on site? Please contact the following person directly.